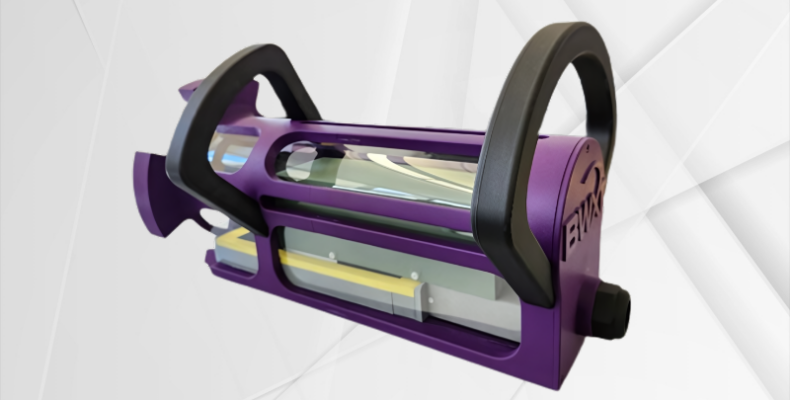

Prototype inspection tool developed by Mohawk College’s Additive Manufacturing

Resource Centre for BWXT Nuclear Energy Canada Inc. (BWXT NEC)

Regardless of the industry or organization, there’s always a need to continue innovating. Sometimes working with external parties is the key to finding solutions.

BWXT Nuclear Energy Canada Inc. (BWXT NEC), a subsidiary of BWXT Canada Ltd., has more than 60 years of extensive experience in the supply of nuclear fuel and fuel channel components, services, equipment, and parts for the Canadian nuclear industry. Its work has included the design and supply of highly reliable nuclear equipment that is used to fuel, inspect, and refurbish reactors. BWXT NEC leveraged support from the Southern Ontario Network of Advanced Manufacturing Innovation (SONAMI) to source a team for an innovative inspection tool.

SONAMI connected Leo Simonis, Manager, System Engineering and Michael Trudeau, New Product Innovations Engineering Lead at BWXT NEC with two of its network members: Mohawk College’s Additive Manufacturing Innovation Centre (AMIC) and George Brown College’s Product Development Exchange (PDx). BWXT NEC partnered with AMIC to develop a prototype of the tool incorporating BWXT NEC’s technology and George Brown College’s PDx to produce a short video.

“What Mohawk created for us was a plastic prototype of what the tool could look like. Having a physical product is important because a potential customer can pick it up, get the feel of it, and then we can add the second layer of the video that George Brown created to show them what the tool could do. Between the two, we can use this to go forward with a potential commercial venture.”

– Michael Trudeau, New Product Innovations Engineering Lead at BWXT NEC

For this project, AMIC created a plastic 3D prototype. Colton David, a researcher at AMIC, developed the prototype inspection tool. The tool had to include a linear slide that could be pushed in and out easily, for inspection purposes. The tool was designed to be lightweight and compact, so it can be operated by an individual wearing full nuclear protective equipment.

“I took pride in this project because nuclear technology is important, and having the opportunity to advance that technology forward was quite rewarding,” said Colton. Not only was Colton the main researcher on the project for Mohawk College, but he is also a recent graduate of Mohawk’s Mechanical Engineering Technology program, and was hired after he graduated last April to work on this project.

“I was surprised by the velocity of design by Mohawk College and how quickly they brought something to life from nothing. We briefed the team as thoroughly as we could, and they very quickly were able to take those designs, refine them down, and print something, which we were very happy about,” said Trudeau.

George Brown’s PDx team headed the development of an engaging video that BWXT NEC could use to show a visualization of the product and how it works. To make it unique, the team incorporated 3D animation, artificial intelligence (AI) voice-over technology and chose to produce the video in more of a ‘commercial’ style.

“As we progressed with the project, it was really important for us to think in the point of view of the audience because we wanted to communicate that technical aspect, which can be challenging,” said Asli Sumer, Project Assistant at George Brown.

As the student on the video portion of the project, Sumer had to learn new software and challenged herself to finetune her skills in processing, as well as modeling and assembly. She also studied BWXT NEC’s specific workflow so that she could effectively conduct analysis that would benefit the industry partner.

“I truly believe that the video George Brown created demonstrates the capabilities of BWXT NEC’s workflow, innovation, new technologies and methodologies to clients, partners, and industry. I’m happy to have been a part of the project. It was a great experience for me and serves as an impressive addition to my resume because I know I can handle industry-level challenges,” said Sumer.

Sumer is currently a student enrolled in George Brown’s Building Information Modeling (BIM) Management program. She’s completing her co-op program and will be graduating in August 2024.

“We found this kind of secret sauce here,” said Leo Simonis, Manager, System Engineering at BWXT NEC. “You get the bang for the buck and can present the problem and have the members quickly provide a solution.”

The BWXT NEC team wasn’t just happy with what they received from this project, but also with what they contributed to it. “We know we’re helping students get the hands-on experience they need to be successful in the future, and plus you never know, it might be a way to connect to future employees for the company,” said Trudeau.

“The results from both Mohawk and George Brown show that the individuals and students working on the project did a great job. We’re already talking about the next phase and continuing the relationship with SONAMI and its members,” said Simonis.

SONAMI leverages faculty, students, and state-of-the-market equipment, together with federal funding through the Federal Economic Development Agency for Southern Ontario (FedDev Ontario) and the Natural Sciences and Engineering Research Council, to conduct projects that provide innovative solutions.

If you would like to discuss your organization’s needs with a SONAMI representative, please contact [email protected].

For 14 years, the Government of Canada, through FedDev Ontario, has worked to advance and diversify the southern Ontario economy through funding opportunities and business services that support innovation, growth and job creation in Canada’s most populous region. The Agency has delivered impressive results, which can be seen in southern Ontario businesses that are creating innovative technologies, improving productivity, growing revenues, creating jobs, and in the economic advancement of communities across the region. Learn more about the impacts the Agency is having in southern Ontario by exploring our investment profiles, our Southern Ontario Spotlight, and FedDev Ontario’s Twitter, Facebook, Instagram and LinkedIn.