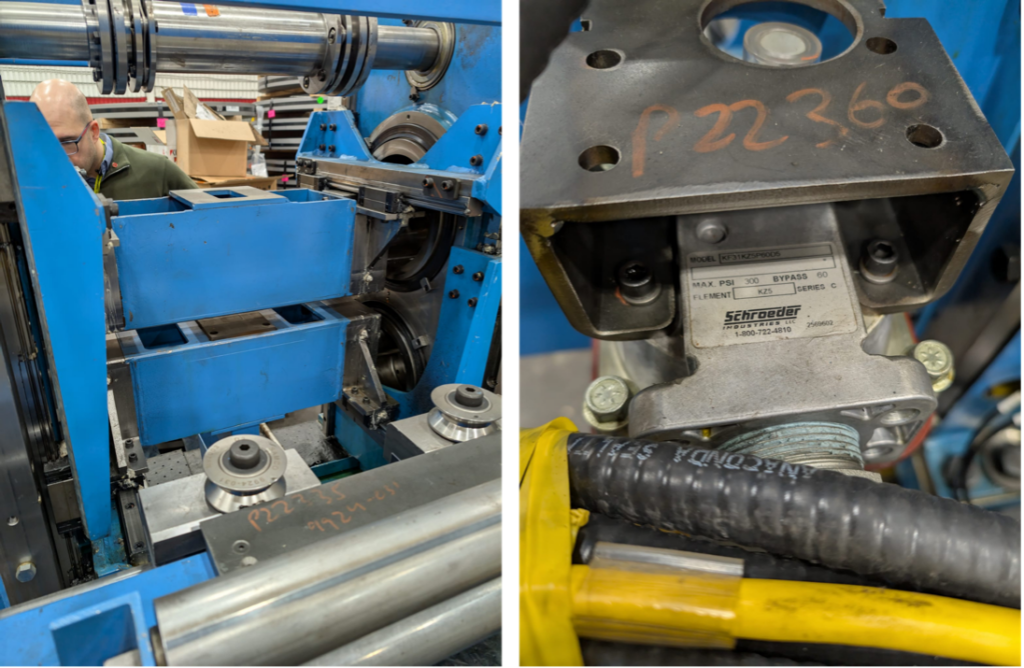

From left to right: Principal Investigator Wladimir Figueiredo with student researchers Bryan Díaz Moscoso and Varvara Nefedova showing a 3D-printed optimized part of the Vortex Press™.

Leveraging support from the Southern Ontario Network for Advanced Manufacturing Innovation (SONAMI), Samco Machinery (Samco) partnered with Centennial College (Centennial) on a collaborative research and development project to enhance the performance and efficiency of their Vortex Press™—a variable-pitch stamping machine used in rollforming.

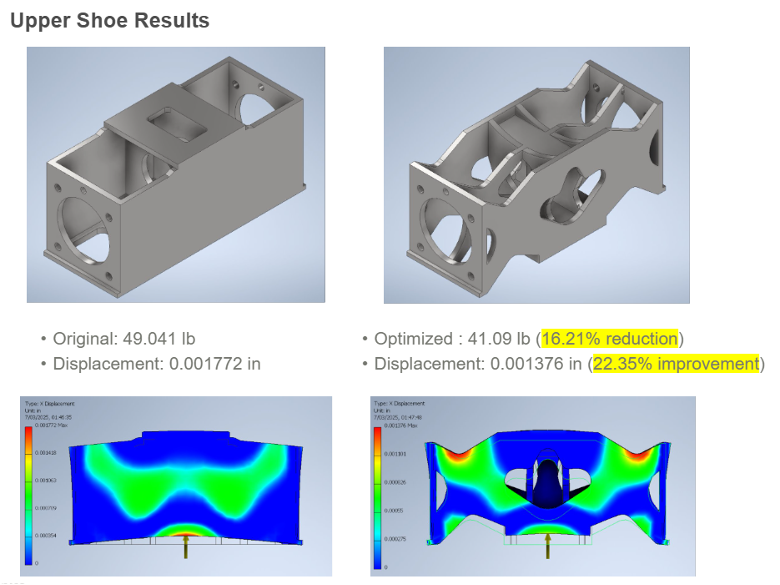

The project focused on optimizing the machine’s design through advanced manufacturing techniques such as additive manufacturing and finite element analysis (FEA), with the goal of increasing production speed, reducing material waste, and improving overall machine functionality.

As a result of the project, the new design had significant weight decrease, leading to an overall 25% weight reduction, improving efficiency and performance of the machine.

“Following the project’s success, this collaboration has also strengthened a unique relationship to bring much-needed visibility to the rollforming industry,” noted Julien Lemaire, Mechanical Engineering Manager with Samco. “As the demand for highly trained mechanical and electrical designers continues to grow, partnerships like this one help equip the future workforce with real-world experience and skills to meet the modern challenges in the advanced manufacturing sector.”

The future of manufacturing depends on innovative solutions that enhance productivity while promoting sustainable practices. Samco, a leading global rollforming equipment manufacturer, partnered with Centennial to overcome a manufacturing challenge. The company wanted to reduce the weight and inertia of the components in its Vortex Press™—a variable-pitch stamping machine used in rollforming, which is a continuous process that converts sheet metal into engineered shapes using consecutive sets of mated rolls—to increase the machine’s speed, efficiency, and subsequently, its marketability to customers.

In October 2024, leveraging SONAMI’s support from the Government of Canada, through the Federal Economic Development Agency for Southern Ontario (FedDev Ontario), Samco began its collaborative applied research project with Centennial’s Applied Research and Innovation division. The project focused on studying the equipment’s components and exploring new design possibilities and manufacturing processes, including additive manufacturing (3D printing). The research team explored material options, created drawings and 3D models using Siemens NX™, performed finite element analysis (FEA), provided cost estimates and supported Samco to modify the equipment.

The new system reduces the amount of metal scrap generated during production, as it is now capable of following the machine’s ramp-up and ramp-down cycles with greater precision. This increase in speed means higher production output with the same workforce, leading to increased productivity for Samco.

The applied research project also offered students valuable hands-on experience. Varvara Nefedova, a student researcher who graduated from the Aerospace Faculty at the Moscow Aviation Institute before joining Centennial’s Electromechanical Engineering, Automation and Robotics program, gained valuable experience through the project. “Working on the project allowed me to work directly with industry partners and learn from their expertise,” she shared. “I picked up new skills like using Siemens NX and improved my report writing and presentation abilities. These experiences have boosted my confidence and prepared me for future challenges in the industry.”

Her classmate and fellow researcher, Bryan Díaz Moscoso, echoed similar sentiments. A graduate in Mechatronics Engineering from the Peruvian University of Applied Sciences, Díaz Moscoso found the project a gateway to new opportunities after coming to Canada. “This project allowed me to work directly with industry partners and helped me develop my communication and presentation skills,” he expressed.

Overseeing and guiding these student researchers and completing the technical research team were two principal investigators, Wladimir Figueiredo and Florin Nijloveanu, professors from Centennial’s Mechanical Engineering Technology program.

“Students conducted multiple FEA iterations while overcoming strict stress constraints, CAD translation challenges, and learning Siemens NX—quickly becoming highly proficient,” said Wladimir, sharing his pride in the students’ achievements. “Their optimized design aimed for around 18% weight reduction, leading to energy savings and increased productivity for our industry partner. Beyond technical skills, this project has equipped students with invaluable problem-solving abilities, setting them up for success in the evolving Canadian manufacturing sector.”

For Samco, partnering with Centennial to innovate the Vortex Press™ further solidified its position at the forefront of the rollforming machine industry. The machine’s speed and efficiency improvements not only ensure the company’s continued relevance but also secure its future with a strong market presence. Additionally, the complexity of the new system, requiring more electromechanical expertise than its predecessor, guarantees the maintenance of highly qualified engineering technology jobs to support and troubleshoot the machines.

Learn more about SONAMI’s impactful partnerships in our Newsroom.

About FedDev Ontario

For over 15 years, the Government of Canada, through FedDev Ontario, has worked to advance and diversify the southern Ontario economy through funding opportunities and business services that support innovation, growth and job creation in Canada’s most populous region. The Agency has delivered impressive results, which can be seen in southern Ontario businesses that are creating innovative technologies, improving productivity, growing revenues, creating jobs, and in the economic advancement of communities across the region. Learn more about the impact the Agency is having in southern Ontario by exploring our investment profiles, our Southern Ontario Spotlight, and FedDev Ontario’s X, Facebook, Instagram and LinkedIn accounts.