LeanSuite partnered with the Walker Advanced Manufacturing Innovation Centre (WAMIC) to upgrade their app and extend it to include Artificial Intelligence (AI) capabilities to automatically categorize the information collected in a meaningful and reportable format. The WAMIC team of researchers and students got to work on the first phase of the project to develop an AI module that was able to read texts sent by app users and assign them to the appropriate categories, such as an idea, complaint, or suggestion. By doing this, they were creating a better solution for the end consumer, removing the overload of admin work and organizing their work. When they kicked off the project, the team at LeanSuite thought that project would only be able to cover one or two of the implementation scenarios, but they received a nice surprise. The WAMIC team went above and beyond by providing a third implementation scenario, that will give them even more food for thought and potentially another avenue of software to investigate in the future.

Meet Angad and Prabhpahul Singh, co-founders and the brains behind LeanSuite, a software development company that offers lean manufacturing and process improvement solutions for manufacturers and companies in other sectors.

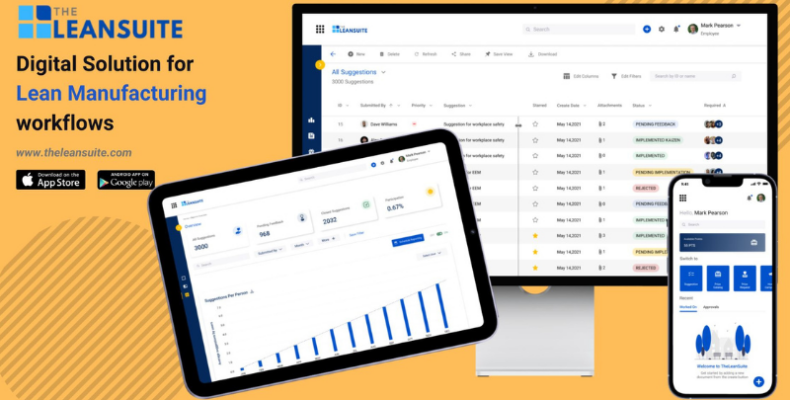

The Brampton, Ont.-based company was created to specifically fulfill the needs of small businesses in terms of operations management and productivity improvement. To support this, LeanSuite developed TheLeanSuite app, a lean manufacturing mobile application that allows workers to quickly capture and report anomalies in production sites, such as broken tools, unusual machine vibration or noises, equipment failures, safety hazards, etc. Once an anomaly is captured, the worker can take a picture and then sends a text to managers for further analysis and decision making.

This app can digitize all your lean manufacturing operations and help foster a culture of lean thinking and continuous improvement.

Now, traditionally, lean manufacturing processes have been very paper and resource intensive. So, there was an opening in the market to develop a software to help organizations implement the lean methodology without having to worry about the administrative efforts.

While the co-founders knew they had a great product, the issue they were noticing was the sheer volume of complaints, ideas or suggestions that managers were receiving.

As it stood, the manager was having to go through each entry individually and manually, causing a fair amount of administrative work for them, which we all know can be quite cumbersome.

Knowing this was the challenge and not having the resources to do the work in-house, Angad and his team knew they were going to need help with finessing their technology.

As fate would have it, their interaction with a local incubator led them to the Southern Ontario Network for Advanced Manufacturing Innovation (SONAMI). This in turn led them to Niagara College, as the leading member of this consortium of applied research institutions addressing advanced manufacturing needs.

LeanSuite partnered with the Walker Advanced Manufacturing Innovation Centre (WAMIC) to upgrade their app and extend it to include Artificial Intelligence (AI) capabilities to automatically categorize the information collected in a meaningful and reportable format.

The WAMIC team of researchers and students got to work on the first phase of the project to develop an AI module that was able to read texts sent by app users and assign them to the appropriate categories, such as an idea, complaint, or suggestion. By doing this, they were creating a better solution for the end consumer, removing the overload of admin work and organizing their work.

The second phase of the project focused on the dictionary setup, data interpretation and machine learning. Now, they are in discussions with the WAMIC team to understand the best approach to implement these changes for the consumer in the production environment, which Angad said he’s especially excited about.

“The team at Niagara College has been super helpful. We provided them with basic information about our challenge, and they were able to come up with innovative solutions. If we would have had to develop it ourselves, it would have taken us significantly more time,” said Angad.

While the implementation is still ongoing, TheLeanSuite team saw the positive internal impacts quickly. Working with WAMIC freed up both time and resources for Angad and his team and has had an impact on their productivity on other parts of the business.

When they kicked off the project, Angad and his team thought the College would only be able to complete one or two of the implementation scenarios, but they received a nice surprise. The WAMIC team went above and beyond by providing a third implementation scenario, that will give them even more food for thought and potentially another avenue of software to investigate in the future.

“I think it’s been a great experience for us. It was reassuring for us to know that we could free up our resources and have experts dedicate their time to our project.”

– Angad Sign, co-founder, Leansuite

Another thing that excited Angad was the initiative and go-getter attitude he saw out of NC staff. “I have to shout-out to Tyler [Heppel, research assistant and student] on the team. We had questions for him around if the algorithm could handle large amounts of data. To our surprise, he was already a step ahead and had started working on optimizing the original piece of code he had written, in an effort to give us the best version of the work possible,” said Angad.

Tyler can attest to the great working relationship as well. He said, “Angad and his team provided a great environment for fostering new ideas and collaborative problem solving. This project gave us an amazing opportunity to explore solutions in Machine Learning and develop new ideas into working programs.”

So, after witnessing that, Angad and Prabhpahul began discussing opportunities to hire NC grads.

“All this impressive work that the College has done for us opened up our eyes to an opportunity. The opportunity being that NC grads have the skill sets we need and hiring them to be part of our team would be a huge asset,” said Angad.

Based on his experience, Angad confirmed he would 100 per cent recommend working with NC’s Research & Innovation team to anyone who is considering it.

Angad said, “I think it’s been a great experience for us. It was reassuring for us to know that we could free up our resources and have experts dedicate their time to our project.”

And working on this project has opened up the door for future work between TheLeanSuite and Niagara College. Angad noted, “Apart from recommending the College to other people I meet, I think we ourselves will be reaching out to the College again because we know we can rely on them to be working on projects in the background if we don’t have the resources to do it ourselves.”

This project, through SONAMI, was made possible by funding from the Federal Economic Development Agency for Southern Ontario.

This success story was based on “Industry partner, Niagara College work together toward continuous improvement in lean manufacturing,” published by Research & Innovation at Niagara College on October 25, 2022.

If you would like to discuss your organization’s needs with a SONAMI representative, please contact [email protected].