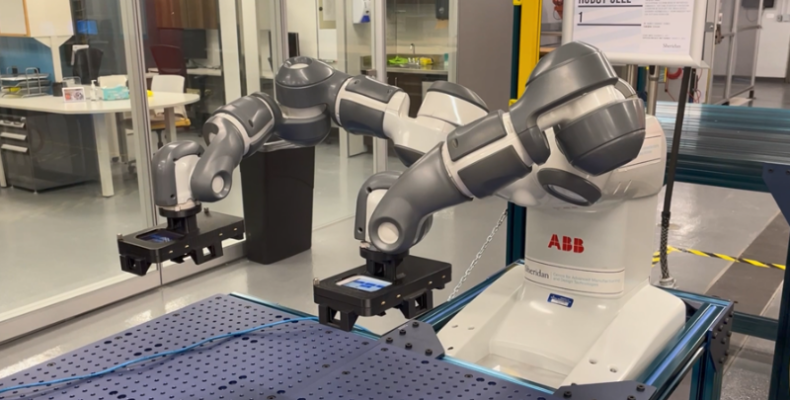

Robotic arm at Sheridan College’s Centre for Advanced Manufacturing and Design Technologies (CAMDT)

Solo riding can be a cathartic experience, giving you a chance to recharge, relax your mind, and stay in the present moment. However, solo rides can also leave you vulnerable if the unthinkable happens. One of the benefits of riding in a group is that it provides an added layer of safety, where fellow riders can call emergency services or an injured rider’s loved ones in the event of an accident.

EatSleepRIDE Mobile Inc. gives solo riders their freedom and peace of mind back through CRASHLIGHT, a ride-tracking and community app. Within the app, motorcycle enthusiasts can sign up for a crash detection feature. CRASHLIGHT uses accelerometer and gyroscope data recorded by a rider’s phone to detect when a crash has occurred. In the event of a crash, a three-minute timer is triggered. If the rider does not cancel the timer before it expires, their pre-set contacts will receive notifications with their location and emergency information.

EatSleepRIDE Mobile’s development team was interested in updating their app to enhance usefulness and accuracy. They came up with an out-of-the-box solution for their testing process that involved using a robotic arm to recreate motion, which would allow them to run tests safely, accurately, and cost-effectively.

Leveraging support from the Southern Ontario Network for Advanced Manufacturing Innovation (SONAMI), EatSleepRide Mobile partnered with Sheridan College’s Centre for Advanced Manufacturing and Design Technologies (CAMDT) with advanced capabilities in robotics.

“What was really impressive was the speed, from the point that the project was discussed to the moment it was initiated. Small- and medium-sized enterprises can greatly benefit from these types of short-term projects that have an immediate impact and offer a lot of flexibility.”

Michael McHale, chief financial officer and digital privacy officer for EatSleepRIDE Mobile

SONAMI is a Niagara College-led network of post-secondary institutions, who, through their respective Research and Innovation Centres, collaborate with small- and medium-sized companies to tackle their manufacturing-related challenges. The organization provides innovative solutions, such as process optimization, designing and testing prototypes, evaluating new technologies, and developing and commercializing new or improved products. SONAMI leverages faculty, students, and state-of-the-market equipment, together with funding from the Federal Economic Development Agency for Southern Ontario (FedDev Ontario), to support manufacturing in Canada.

With SONAMI’s support, EatSleepRIDE Mobile had access to a robotic arm that could mimic motion and expertise to help them carry out the tests they required. The aim of the study was to systematically investigate if increasing the inertial measurement unit rate of x1 (10Hz) signal frequency to x2 over sampling (20Hz) or x10 over sampling (100Hz) would increase measurement accuracy. According to Nyquist Sampling Theorem a sampling rate must be at least a x2 oversampling would be needed to obtain an accurate measurement.

“We suspected that sampling at x1 was not sufficient and started looking for a location where we could carry out testing,” said Michael McHale, chief financial officer and digital privacy officer for EatSleepRIDE Mobile. “I have a robotics background and thought that testing using a robotic arm would be perfect because it provides a repeatable controlled environment. This is not possible on a motorcycle where every ride is so different.”

During the study, a series of clearly defined motions were recorded using a pair of collaborative robotic arms attached to custom detachable phone enclosures. Coop students from Sheridan College designed a rigid mount that could hold a variety of phone brands on the robotic arm during testing. The mount was produced at CAMDT using their 3D printing and manufacturing capabilities.

Watch the robotic arm in motion:

Three coop students participated in the project, from two post-secondary institutions. Darius Innis and Zain Panjwani, were completing Sheridan College’s Mechanical Engineering Technology program. They worked on designing the phone enclosures and programming the robotic arms for CAMDT. Rosalind Liang, was finishing a Bachelor of Science degree at the University of Toronto with double majors in Astronomy and Astrophysics, and Neuroscience. Liang was also completing a one-year coop position in data science at EatSleepRIDE Mobile. During the project she designed the experimental procedure, as well as collected and analyzed the data for the company.

“The experience that students received in this project was invaluable and assisted them in several ways,” said Ramzy Ganady the principal investigator for the project and the research technologist for the Centre of Advanced Manufacturing and Design Technology. “Mechanical engineering students are not used to testing cell phones with robotics, so they got to think outside of the box. Also, the students received useful experience from designing the mount for the robotic arm.”

Through the project EatSleepRIDE Mobile was able to back up its hunch with scientific data, which assisted them to take the next steps in updating their app. The results showed that the current sampling rate of x1 signal frequency was not sufficient and that implementing an x2 oversampling rate in the app would result in more accurate detection of crash events by CRASHLIGHT.

McHale was very pleased with the collaboration with CAMDT, through the project funded by SONAMI. In the next phase of the experiment, EatSleepRIDE Mobile plans to double the sampling rate for a pilot group of riders, prior to implementing the change on the app for the public.

“What was really impressive was the speed, from the point that the project was discussed to the moment it was initiated,” explained McHale when describing the process of initiating the project. “Small- and medium-sized enterprises can greatly benefit from these types of short-term projects that have an immediate impact and offer a lot of flexibility.”

If you would like to discuss your organization’s needs with a SONAMI representative, please contact [email protected].